In the world of modern manufacturing, converting an idea into a physical entity isn’t just restricted to blueprinting or creating digital designs. The post-implementation world: All complex projects demand clear communication, enough planning that outcomes are already visualized each before any implementation in the real world happens. Physical Models Is Where It’s At The models are therefore bridges from the world of imagination to the realm of execution, providing concrete, practical approaches to ensuring that even highly complex behaviors work. These models provide a smarter, clearer way forward for industrial project development, for planning stages or demonstration & decision-making. This article discusses how these tools take wild ideas and turn them into real-world successful ones.

What Are Industrial Models?

Industrial models are tailor-made scale production models such as for example a manufacturing plants, machinery setups or a production systems. These physical models provide an unambiguous and precise representation of the plant or system in reality.

Finely detailed industrial models, these are complex systems associated with highly industrial structures and setups designed thorough a process that involves architectural designing, engineering utility, and imaginative craftsmanship for exactly mimicking the art of retaining industrial culture. Whether you are building a manufacturing facility mock-up or a scale industrial model prototype to visualise those complex ideas.

Why Industrial Models Matter

For any industry that requires precision, safety and efficiency, a visualisation tool that can communicate complex information in seconds is invaluable. How Industrial Models Add Value:

Improved Planning and Decision-Making

Large companies test production lines in factory layout visualizations to determine workflows, where machinery should be placed and how to efficiently utilize space before constructing a new facility. Industrial models enable decision-makers to anticipate obstacles and implement informed changes.

Effective Engineering Presentations

To Engineers, image is everything. The industrial models bring engineering model presentations to life by providing a real-world reference that takes the complex ideas and presents them in a digestible format for stakeholders and leas technical team members.

Training and Simulation

Practice runs in a manufacturing facility are very common for new employees training. They ease the learning curve for labour to see how your systems operate without costing a leg and an arm in real setup costs.

Marketing and Client Demonstrations

Industrial models serve an everlasting purpose, whether in stand-ins or exhibitions, client meets or investor stage. A production-ready custom model helps depict your vision and technical abilities in a way that is attractive and unforgettable.

Types of Industrial Models

Industrial model makers make less types of models that those for otherspecilized market, but deeding on the scope there are a few differentmodels to get.

- Scale Industrial Model Prototypes

These are large industrial-systems-level models mapped in fine detail at small scale, typically used for research and development. They are used to visually see how the product will flow, test out functionality of production layout and it is also used as a demonstration for an idea before complete implementation.

- Factory Layout Visualization Models

These models are centered around geometric optimisation of the space, slotting in machine and human parts and improving the actual workflow architecture. They are ideal for plant developers, architects and production planners to help prevent layout problems beforehand.

- Interactive and Functional Models

In this economy you can find models with moving parts, lighting effects or even augmented reality to demonstrate real life processes. These tend to be high-resolution attention grabbers, perfect for trade shows or presentations with a lot on the line.

Selecting the Perfect Plant Model Makers For Industrial Plants

Some model makers are better than others. Find an expert who pays attention to the little things and has done custom-built production models before. When building a scale model industrial plant, the best makers work off CAD data and technical drawings to create an accurate model to your specific requirements.

Ensure your model maker is able to customize for the industry you serve, be it oil&gas, pharmaceuticals, automotive or food processing. An experienced provider will appreciate what you are trying to accomplish with your design and suggest the best materials, size, and add-ons to give your model the wow factor that you are looking for.

Real-World Applications of Industrial Models

Below are the few conditions under which industrial models can be demonstrable:

Future Facility Planning: See your plant in its entirety before starting any construction.

Product Line Expansion: Show how new equipment fits in an existing layout.

Safety Training — Show emergency Exits, Handling Equipment and Work Flows.

Investor Pitches: Build investor confidence and excitement using a high quality tool

Trade Show Displays – Interactive Models that attract attention and can visually explain your concept in seconds.

Why Choose Macomatech?

Macomatech builds confidence, not models. Our specialized team combines meticulous practical experience with a maestro-grade precision for translating the complex industrial and architectural provender into intricate, precise, and affecting scale models. This is why the top companies, developers and Engineers always choose us :

🔹 Expert Craftsmanship

All models are carefully selected and well made of high-quality materials with the most modern methods. Our skilled artisans ensure each piece reflects the most intricate details of your design.

🔹 Industry-Specific Knowledge

And we know the technical and visual requirements of sectors such as manufacturing, energy, real estate, infrastructure. This way, we are able to provide not only visually compelling models but also functionally informative.

🔹 Customization & Flexibility

Every project is different — and so is our approach. Customizing each model to fit the size and scale of your process, Constraint Manufacturing can accommodate either downstream small component or a large facility.

🔹 Cutting-Edge Technology

Macomatech uses high-tech tools that respect the artistry and craftsmanship of traditional fabrication settings, such as vacuum forming, laser cutting, 3D models, and CAD for precise tolerances.

🔹 End-to-End Support

Our team is with you from initial concept consultation to production, delivery, and display setup — ensuring this process is easy, quick and stress-free.

🔹 On-Time Delivery, Every Time

We respect your deadlines. And our processes, coupled with our dedication to quality, mean that when you require a model from us it is always ready — and finished the right way.

Conclusion

Seeing an idea is the first step to actually implementing it and in manufacturing you need to be clear about what you want. This gives a tangible version of the idea, which then helps to increase comprehension, reduce risk and get better decisions. They are not merely stand-ins, but also tools with which to signal intention, refine strategy, or develop a trust among clients, teams or stakeholders. Not only are these models implementable at scale in a vastly industrial landscape, but they actually offer more than just appearances -they foster functional efficiency, accuracy and innovation. Are you creating your next masterpiece with a sharp vision in mind, well perhaps the best attempt.

More Stories

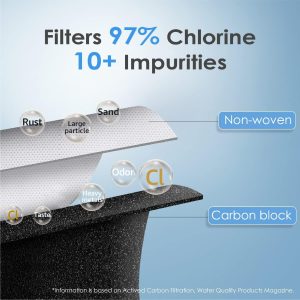

A Clean Water Lifestyle: Strengthening Family Health and Supporting a Sustainable Future

GiftCardMall – The Ultimate Destination for Convenient and Safe Gift Cards

London Bodyguard Services: Premier Protection in Britain’s Financial Capital